Choosing the Right 3D Printer Filament for Automotive Applications

Selecting the right filament is crucial for successful 3D printing, especially in automotive applications where parts need to withstand various stresses and environmental conditions. This guide will explore the pros and cons of different filament types, including PLA, ABS, PETG, Nylon, and resin, and provide recommendations for their use in automotive settings.

PLA (Polylactic Acid)

PLA is one of the most popular and easy-to-use filaments available. It's biodegradable and has a low printing temperature.

Pros

- Easy to print with

- Biodegradable

- Wide range of colors available

Cons

- Low melting point

- Brittle compared to other materials

- Not suitable for high-stress applications

Automotive Applications

PLA is best suited for testing part fitment or very simple parts that will not see much heat or stresses. Vehicle interiors can get hot enough on a summer day to partially melt and deform PLA. it is generally not recommend for automotive parts

ABS (Acrylonitrile Butadiene Styrene)

ABS is known for its strength and durability, making it a popular choice for automotive parts that require higher impact resistance.

Pros

- Strong and durable

- Higher melting point than PLA

- Can be post-processed with acetone for a smooth finish

Cons

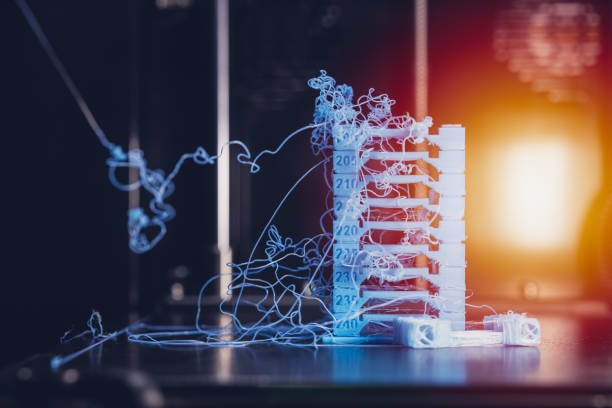

- Warps easily during printing

- Produces fumes that require ventilation

- More challenging to print than PLA

Automotive Applications

ABS is best suited for under-the-hood components, brackets, and functional parts that need to withstand higher temperatures and mechanical stress.

PETG (Polyethylene Terephthalate Glycol)

PETG combines the ease of use of PLA with the strength and durability of ABS, making it a versatile filament for various applications.

Pros

- Strong and flexible

- Resistant to impact and temperature

- Minimal warping

Cons

- Can be stringy during printing

- Requires fine-tuning of print settings

- Not as heat-resistant as ABS

Automotive Applications

PETG is suitable for exterior parts and functional components that need to be both durable and flexible, such as protective covers, clips, and mounts.

Nylon

Nylon is known for its high strength, flexibility, and resistance to wear, making it an excellent choice for demanding applications.

Pros

- Extremely strong and durable

- High impact resistance

- Resistant to wear and abrasion

Cons

- Absorbs moisture easily

- Requires high printing temperatures

- Difficult to print

Automotive Applications

Nylon is perfect for mechanical parts that require high strength and flexibility, such as gears, bushings, and custom brackets. It can be used for many similar parts as ABS that dont require as rigid of a material

Resin

Resin printing, typically done with SLA (Stereolithography) printers, offers high detail and smooth finishes but has different material properties compared to filament-based printing.

Pros

- High resolution and detail

- Smooth surface finish

- Ideal for small, intricate parts

Cons

- Brittle compared to filament materials

- Requires post-curing

- Resin can be messy and toxic

Automotive Applications

Resin is best for creating detailed, small parts such as connectors, custom badges, and intricate interior components. It can also withstand incredibly high temperatures but is often quite brittle.

Carbon Fiber Reinforced Filaments (CF Filaments)

Carbon fiber reinforced filaments, such as CF Nylon, are infused with carbon fiber strands to enhance strength and stiffness, making them ideal for high-performance applications.

Pros

- Extremely strong and stiff

- Lightweight

- High heat resistance

Cons

- Abrasive to nozzles (requires hardened nozzles)

- Can be brittle

- More expensive than standard filaments

Automotive Applications

CF filaments are ideal for parts that need to withstand high mechanical stress and temperatures, such as engine components, structural brackets, and high-performance custom parts. CF Nylon & CF ABS can be easier to print than standard version, having more dimensional stability and being less prone to warping during printing.

Conclusion

When it comes to 3D printing for automotive applications, choosing the right filament is crucial. Here's a quick recap of the best filament types for different needs:

Best Overall: PETG - Combines ease of use, strength, and flexibility.

Best for High Temperature Applications: ABS - High melting point and durability.

Best for Durability: Nylon - Superior strength and wear resistance.

Ready to start your next automotive 3D printing project? Visit Auto Print Parts to explore our wide selection of 3D printable car parts and find the perfect filament for your needs.